We’re dotting our i’s and crossing our t’s on the KBDi Design Conference 2024 program, and we can’t wait to share the...

Knowledge and Know How

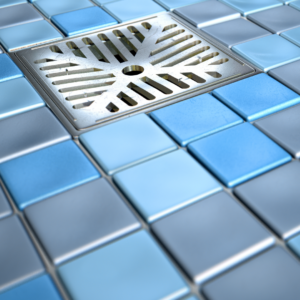

Floor Wastes and Falls to Wastes | NCC Requirements

The National Construction Code (NCC) Volumes One and Two, and associated Housing Provisions, set out specific...

Wet area waterproofing and new NCC requirements

The new ABCB Housing Provisions standard is part of a significant format change to the National Construction Code...

NCC, AS and the KBDi Technical Support Service

When starting a new kitchen or bathroom design, it's essential to have a clear understanding of the regulations...

What is deemed a defect in a new kitchen or bathroom installation?

We're often asked what is considered a defect in new kitchens and bathrooms. The question sometimes comes from...

Understanding Slip Ratings in Residential Applications

Members often ask us about the legislated requirements for slip-resistant flooring in domestic applications. We've...

Benefits of Ducted vs Recirculating Rangehoods

A message from our Corporate Partner, Schweigen If you’re in the market for a new rangehood, you might feel a bit...

The difference between project consultancy and project management

In most states of Australia, project managing new construction or renovations requires a particular licence. If you...